依托日本先进技术积淀,由曾在日本深造研究的王志龙博士带领核心团队深耕创新,成功研制出国内首台自动化光纤研磨设备。通过跨学科仿真实验与持续迭代优化,设备研磨良率突破90%,尽显卓越品质。

2024年,第二代自动化光纤研磨设备震撼发布!作为全面升级的旗舰产品,它搭载全自动化软硬件平台,配备智能自动清洁系统,大幅降低人力成本,以科技赋能行业高效生产,引领光纤研磨领域智能化革新!

专访凤凰光腾:突破多家头部微连接客户 独特研磨路径技术赢得稳

9/10/2025,光纤在线讯,2024年,凤凰光腾率先推出业界首款MT/MPO全自动研磨机,有效地解决长期以来MPO研磨繁琐的工艺制程,行业里掀起了一股全自动研磨之风。近日,光纤在线编辑采访了凤凰光腾首席科学家王志龙博士和总经理张建刚先生,深入了解其独特的研磨工艺技术,如何持续推进其自动化生产设备改革。 第三代全自动研磨机:模块化设计引领行业革新凤凰光腾最新推出的第三代全自动研磨机采用了创新的模块化系统集成概念,更好地满足客户对一部分工艺集成的需求,有效地弥补了客户生产线中薄弱的环节。 “模块化集成是将可独立设计的子系统,按照一定规则构成更复杂系统的技术,我们将这一理念完美应用到了第三代产品中。而和之前推出的主要针对短纤产品进行全自动工艺集成的第一代产品相比,第三代产品实现了质的飞跃,覆盖了 MT-FA 和 Cable 两大产品线。”凤凰光腾总经理张建刚提到。 在光通信自动化设备领域,稳定性就是企业的生命线。“我们深知,一台设备的故障可能导致整条生产线停滞,给客户带来巨大损失。因此,从公司成立之初,我们就将设备的稳定性和可靠性放在首位。我们所有的产品设计,均会通过各种模拟仿真试验,再根据仿真结果持续做优化,最终实现了高达90%以上的端面良率水平。此外,3D几何面型合格率高达100%,并与国内外多家研磨耗材厂家联合试验,不断改进研磨耗材配方及比例,不断调整研磨路径轨迹,让研磨出来的核心参数不断提升。” 凤凰光腾首席科学家王志龙博士直指公司的核心发展理念。 而这种理念并非空洞的口号,而是体现在产品全生命周期的每一个细节中。据介绍,凤凰光腾的设备在出厂前都要经过严格的品质把控,包括长时间的空载运行测试,确保设备在各种工况下都能保持稳定。同时要求每一台设备都必须通过客户小批量生产的 2D/3D/光学性能等检测验证,只有完全符合标准的产品才能交付客户。 这种严苛的标准使得凤凰光腾的产品在国内外巨头企业的千万只产品测试中脱颖而出,赢得了市场的广泛认可。 此外,为了迎合海外客户对于自动化设备安全性的要求,凤凰光腾所有的设备严格遵循欧盟 EN 62368-1:2014 标准,通过了 CE 认证,完全符合国际安全标准。 这种对国际标准的严格遵循,不仅体现了凤凰光腾对产品质量的极致追求,也彰显了公司开拓全球市场的决心。目前,公司产品已获得多个海外客户的认可,开始在国际市场崭露头角。 核心技术突破:自主知识产权轨迹研磨技术 据了解,凤凰光腾的全自动研磨机在MPO/MT连接组件的市场占有率高达90%,几乎所有头部企业都拥有至少一台凤凰光腾的全自动研磨设备,而如此高的市场占有率,背后是对凤凰光腾自动化产品稳定性和可靠性的认可。 王博士介绍,凤凰光腾的全自动研磨机的核心竞争力在于其拥有自主知识产权的轨迹研磨技术。凤凰光腾是业界除德迈尔、精工、NTT 之外第四家拥有独特轨迹研磨技术专利的企业,标志着中国企业在高精密连接制造设备领域实现了重大突破。 凤凰光腾独特的轨迹研磨技术最大限度地提高了研磨耗材的利用率,这得益于王博士多年来在精密制造领域的研究积累,同时凤凰光腾联合西安理工机械与精密仪器工程学院共同开发验证,这一精密设计使得凤凰光腾的设备帮助客户降低了生产成本,提高了产品质量稳定性,带来了显著的经济效益。 聚焦高精度MT组件生产:满足 800G/1.6T 光模块需求 “800G/1.6T 光模块对光纤的一致性要求非常高,特别是光纤连接器的一些光学性能指标需要保持极高精度的控制。” 张总强调,这正是凤凰光腾设备的优势所在。通过自主知识产权的轨迹研磨技术,设备能够实现亚微米级的精度控制,完全满足新一代光模块的制造需求。 据了解,800G/1.6T 光模块对核心的高密度连接器件的制造精度、尺寸、损耗要求极高,而凤凰光腾的第三代研磨机凭借其卓越的性能,已成功切入这一高端器件市场,成功突破了多家面向头部光模块企业的领先的光器件制造商,为国内外光模块厂商的核心供应商提供关键设备支持。 全方位服务:设立多个 FAE 现场技术支持中心 除了高可靠、稳定的产品,凤凰光腾更将“全方位服务”视为核心竞争力。公司正围绕微连接主力制造基地,布局多个 FAE 现场应用工程中心,就地提供调试、优化与培训。设备到场后最快 7 天即可小批量投产,真正做到“交付即产能”。 这种 “产品 + 服务” 的模式,使得凤凰光腾在激烈的市场竞争中形成了独特的优势,赢得了客户的广泛好评。 展望未来,凤凰光腾已经制定了清晰的技术路线图。公司下一步将重点攻关两个方向:一是实现清洁和自动判定的智能化,进一步提升设备的自动化水平;二是突破 FAU(光纤阵列单元)生产的自动化瓶颈。 结语:创新铸就未来通过本次专访,我们深刻感受到凤凰光腾对技术创新的执着追求和对产品质量的极致要求。从将稳定性视为生命线,到自主研发核心技术打破国际垄断,到布局全球服务网络,凤凰光腾正以实际行动诠释着中国智造的实力。

Analysis of the development st

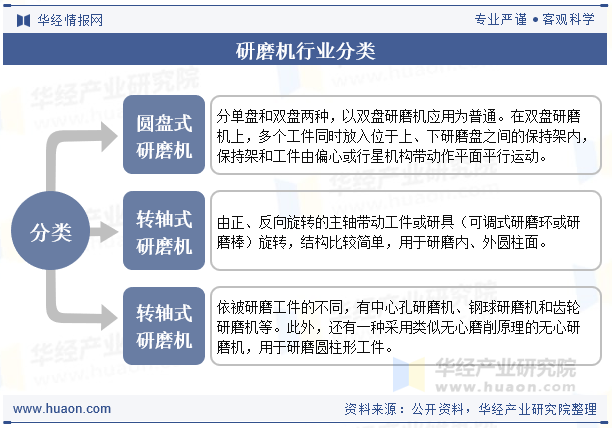

1. Overview of grinding machine manufacturing industry A grinding machine is a grinding machine that grinds the surface of a workpiece with a grinding tool coated with or embedded abrasive. It is mainly used for grinding high-precision planes, inner and outer cylindrical surfaces, conical surfaces, spherical surfaces, threaded surfaces and other profiles in the grinding workpiece. The main types of grinders are disc grinders, rotary shaft grinders, and various special grinders。 2.the grinding machine manufacturing industry chain 1. Industrial chain structure diagram The upstream of the grinding machine manufacturing industry chain includes raw material suppliers and parts manufacturers, among which the raw materials mainly include steel, and the quality and 。

In front of the South African

This is truly a grand banquet.In front of South African President Ramaphosa and numerous journalists, Trump suddenly ordered to turn off the lights and put on the TV.He had already prepared a large television in his presidential office.The video being played shows a South African opposition black leader roaring: ‘Kill the Boers.’.The Boers are descendants of the Dutch and white South Africans.I saw that many Western media outlets’ immediate reaction was that this was a deliberate ambush by Trump, a public humiliation of Ramaphosa, and an attempt to accuse South Africa of genocide against white people.Previously, white people were the ruling class of black people in South Africa, implementing racial 。